Customized service

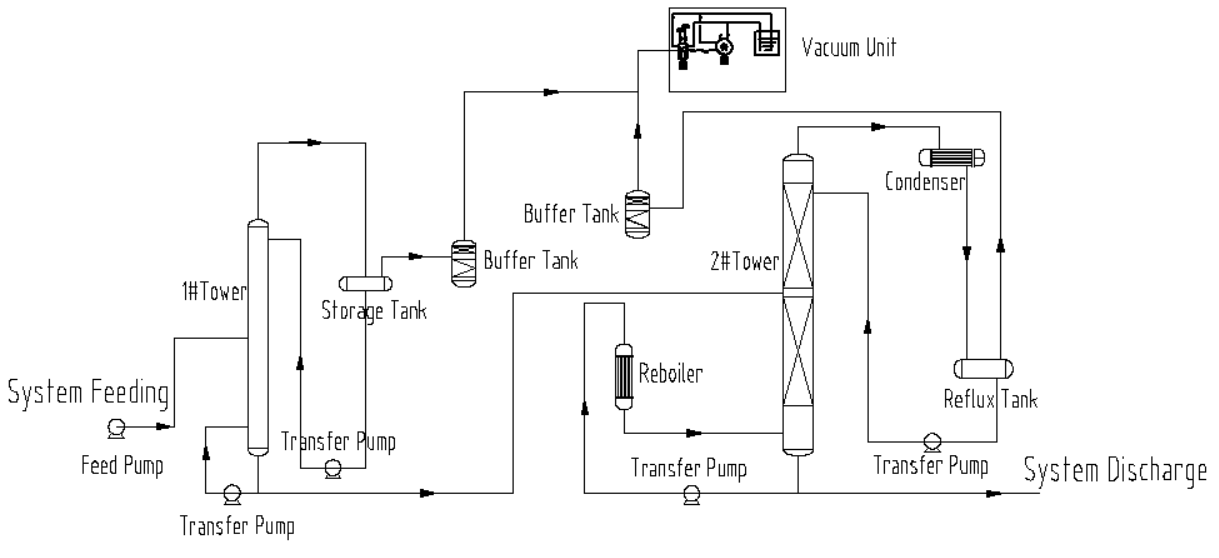

The distillation system can achieve in the actual production conditions, by adjusting and controlling the material residence time, operating temperature, operating pressure, flow rate, the speed of the related dynamic equipment, start and stop process parameters, to achieve different characteristics of the material for distillation purification, adjust the purity and yield of the target material. Widely used in fine chemical, food, medicine, environmental protection and other industries.

The distillation system is based on customer requirements and product characteristics. Can provide customized system related services:

- Packing type: mesh corrugated, corrugated hole plate, metal ring, porcelain ring and other types

- Rectification column type: plate column, packing column

- Material selection: 304/316L/2205/ Hastelloy etc

- Continuous feed/discharge is available

- Temperature control method (steam/heat conduction oil/circulating water, etc.) is available

- PLC/DCS/ visual operating system is available

- Multistage series-parallel combination distillation system is available for configuration