Customized service

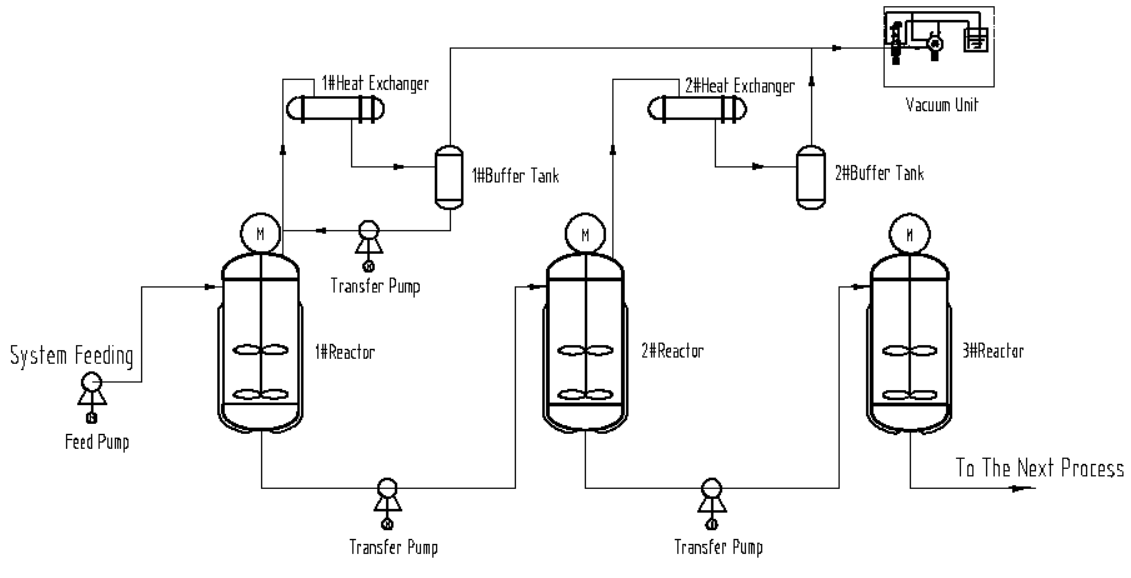

The oligomerization system can realize the dehydration esterification, concentration polymerization, adjustment and control of molecular weight distribution of customer materials under different pressures and temperatures by adjusting and controlling the process parameters such as material residence time, operating temperature, vacuum degree, flow velocity, speed of all related dynamic equipment, start and stop, etc. Widely used in fine chemical, food, medicine, environmental protection and other industries.

The oligomerization system is based on customer requirements and product characteristics. Can provide customized system related services:

- Mixing forms: anchor type, folding type, push type, frame type, spiral belt type, etc

- Motor type: frequency conversion, fixed frequency, explosion proof, etc

- Material selection: 304/316L/2205/ Hastelloy etc

- Continuous feed/discharge is available

- Temperature control method (steam/heat conduction oil/circulating water, etc.) is available

- PLC/DCS/ visual operating system is available

- Multistage series-parallel combination oligomerization system is available for configuration