Melt crystallization technologies remove heat and cool the liquid to create a driving force for the formation and growth of crystals. Melt crystallization provides an economic and energy-efficient alternative purification step in cases where standard distillation is unsuitable due to close boiling isomers, azeotropic systems, products that tend to polymerize, heat sensitive products, or explosive substances. The suspension based process provides slow growth rates that allow pure crystal formation even in relatively impure melts. By combining this extremely selective crystallization system with our proven washing column technology that separates the crystal from the mother liquor, an ultra-pure product can often be obtained after one step.

Verification of the results of the laboratory tests under real process conditions

Determination of design parameters for industrial scale melting crystallization in the future

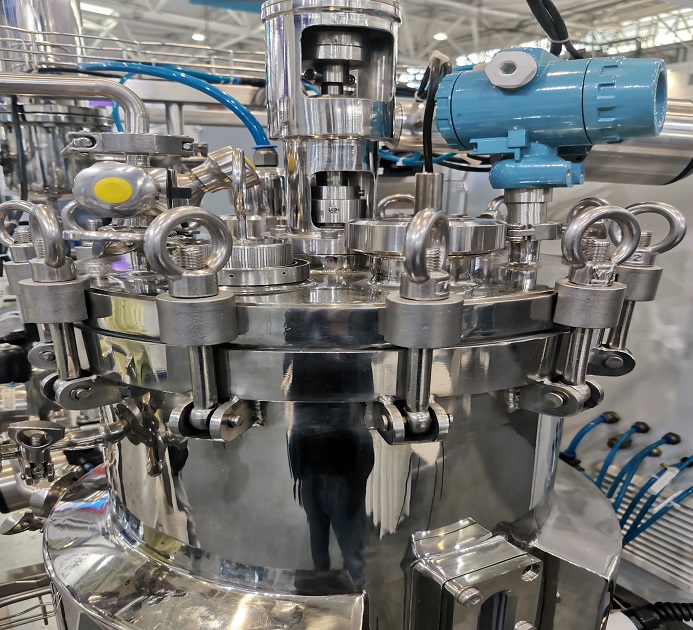

Equipment materials involved: 316L stainless steel/duplex stainless steel 2205/Hastelloy

Dimensioning of process equipment and aggregates of the industrial plant

Production of sample up to several tons

Required raw material quantities about 50-500KG

Monitoring of the product properties during pilot test

Main Properties

- Processing capacity : 50kg/h to 500kg/h (common)

- Heating temperature : up to 350 ℃ (heat transfer oil heating), other heating methods can be customized

- Operating pressure : from full vacuum to positive pressure

- Manufacturing material : 304/316L/2205/Hastelloy

- Rotating equipment speed : variable frequency speed regulation

- Dwell time : Adjustable

- Continuous reaction : Yes

07

Temperature Control System

09

Instrument valve and pipeline system

Standard Parameters

| Type/Name |

Volume |

Feed Rate/Handling Capacity |

Required Crude Amount |

| Crystallizing tank(JJG-1500-001) |

1.5m³ |

165kg/h |

Normally500kg |

| Separating tower(FLT-160-001) |

28L |

165kg/h |

Normally500kg |

| Crystal tank(YJG-1500-001) |

1.5m³ |

315kg/h |

Normally500kg |

| Scrubbe(XDT-160-001) |

28L |

315kg/h |

Normally500kg |

| Storage tank(CG-1500-001) |

1.5m³ |

150kg/h |

None |

Customized service

The melt crystallization system can realize the crystallization, separation, washing, purification and other operations of materials with different characteristics under the actual production conditions by adjusting and controlling the process parameters such as material retention time, operating temperature, operating pressure, flow rate, rotating speed of various related dynamic equipment, startup and shutdown.

The melt crystallization system is based on customer requirements and product characteristics, Customized system related services can be provided:

- Crystallization form: suspended melting crystallization, cooling crystallization, evaporative crystallization, etc.

- Solid liquid separation: separation tower, screw type, centrifuge, filter, etc.

- Material selection: 304/316L/2205/Hastelloy, etc.

- Continuous feeding/discharging available.

- Temperature control mode (steam/heat transfer oil/circulating water, etc.) available.

- PLC/DCS/visual operating system available.

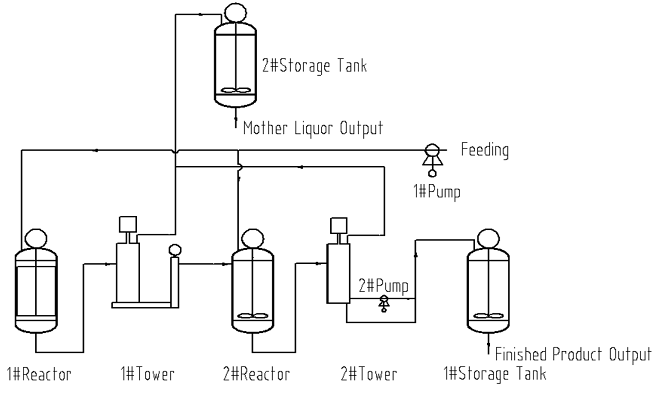

- Multi stage series parallel combination melting crystallization system is available for configuration.